FOB Price

Get Latest Price1 ~ 150000 / Set ( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

-

FOB Price:

1 ~ 150000 / Set ( Negotiable ) Get Latest Price

Place of Origin:

CHINA

Price for Minimum Order:

1 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

WOODEN BOX

Delivery Time:

3MONTH

Supplying Ability:

6 Set per Month

Payment Type:

T/T

Product Group :

-

Contact Person sue

Taizhou, Jiangsu

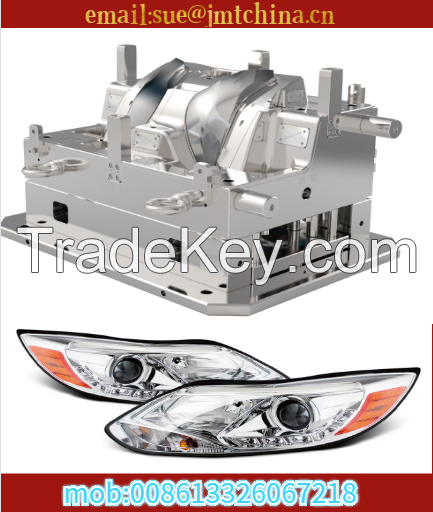

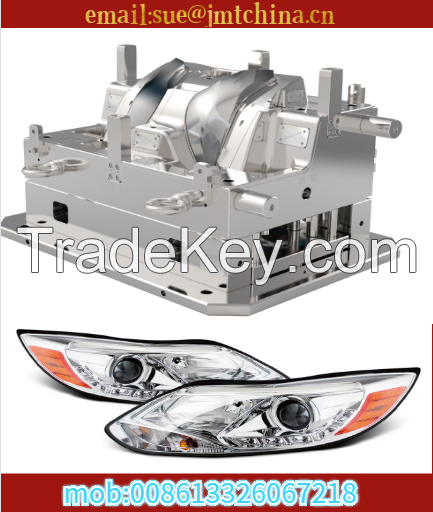

Are you a looking for good Lamp mold maker in china?, molder or OEM working ? Have you met with your industry colleagues recently? Taizhou huangyan JMT mold co.,ltd is one of the famous mould factory in Zhejiang China. JMT Mould isspecialized in Lamp mould design and process From ***2 until today.

We making car lamp mould for customers all over the world both in OEM and aftermarket .We sevice for SUZUKI,TOYOTA,REYNOLDS,HONDA and so on .

There are three important steps in a head lamp & tail lamp mould project, first of all is the mould design. As you know. JMT company get more than *0 designers and they are all with rich experience with mould design. Mould design is called the key of a good quality mould as so many straucture in a mold ,like insert/slider/undercut/ and so on, if without good design you have trouble in the future, Especially the car light mould, its huge and hard jobs .You need design the cooling system as well as the eject / hot runner system.

Second is the mould process. Its so important so that require high precision processing machins. JMT company invest lots of money with those process machines. In the lamp mould Process ,there are many jobs need to do, like: engaving / CNC milling / electric spark / drilling /tempering / texture/argon arc welding and so on. Such a long line of process so decide one hundred working days for finish the lamp mould then we move to the mould trial.

Thirdly is the fitting. Its the last job of the mould project. when we got the mould trial sample we have to assemble it on the car to check if is everywhere in good fiting, if here no problem we can ship the mould. if still some we will check injection lamp mold design and process and find the problem and solve it.

BASIC INFOMATION

|

Name |

Fog lamp cover mould |

|

Plastic resin |

ABS |

|

Mould dimension(mm) |

**0x**0x**0 |

|

Mould weight (T) |

1.*8T |

|

Mould cavity steel |

1.***8 |

|

Mould Core steel |

1.***8 |

|

Manufacture time (day) |

*5~*5 DAYS |

|

Mould life (ten thousand) |

≥*0 |

|

Cycle time |

*5~*0 S |

|

Cooling line connector type |

DME NS**0 SERIES quick coupling, connected to main water manifold by FST**0 MS joint connector, excellent cooling system design |

| Country: | China |

| Model No: | - |

| FOB Price: | 1 ~ 150000 / Set ( Negotiable ) Get Latest Price |

| Place of Origin: | CHINA |

| Price for Minimum Order: | 1 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | WOODEN BOX |

| Delivery Time: | 3MONTH |

| Supplying Ability: | 6 Set per Month |

| Payment Type: | T/T |

| Product Group : | - |