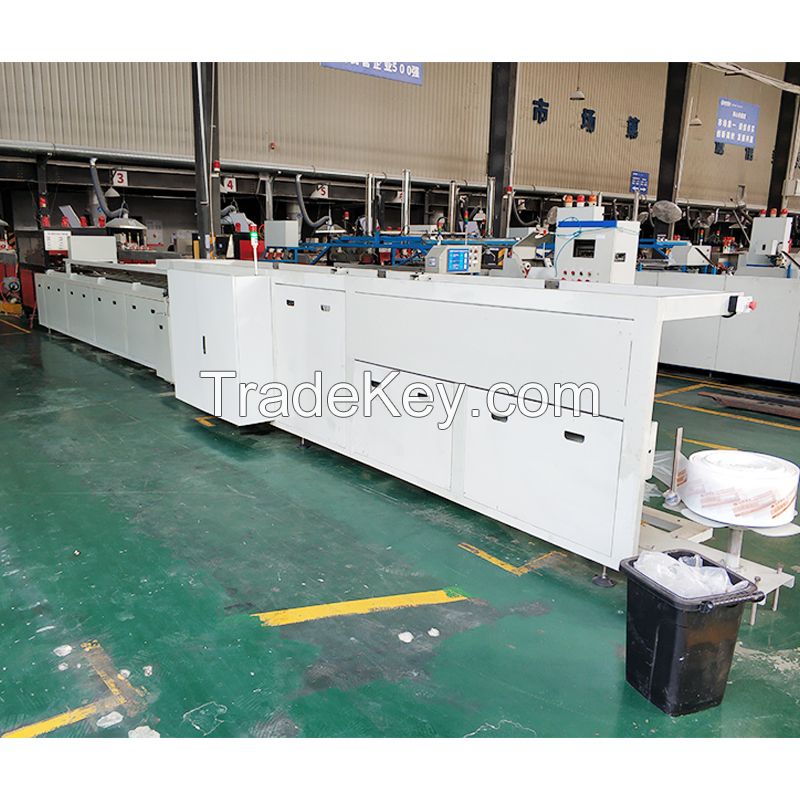

Product Description

This equipment meets the requirements of fully automatic counting,

weighing, automatic removal of unqualified pipes, joint sorting,

winding and bundling, bagging, and placing into independent

finished product boxes for straight tube products produced by a 1

out 4 (or 1 out 2) straight tube extruder (with the production

speed and packaging quantity of the *0 type extruder). The ultimate

goal is to achieve a fully automated production line that operates

unmanned for *4 hours a day, except for replacing winding and

packaging films.

2、 Main features:

1. The traction cutting machine directly connects to the extruder,

which is a fully automatic packaging process for counting,

weighing, organizing, winding and bundling, bagging, and placing

straight pipe materials into independent finished product boxes.

The overall system operates at a fast and stable speed, which can

meet the production speed of existing line pipe extruder equipment

for packaging.

2. Programmable PLC control, servo drive, and touch screen settings

for personalized parameters. The system has functions such as

historical alarm recording, fault recording, adjustable packaging

process and pipe length parameters, making the entire packaging

process efficient and complete.

3. Automatic counting and weighing dual detection, ensuring

accurate and accurate quantity of each package of pipes.

4. Each pipe can be individually tested for quality and

automatically adjusted.

1) Automatically detect the alarm signals of each pipe (such as

vacuum alarm, spray code alarm, etc.), and automatically drop the

waste pipes that generate the alarm into the waste box on the

outside of the equipment, without affecting the counting and

packaging of other normal pipes.

2) The automatic weighing of a single pipe can be carried out

during the production process to provide inspection personnel with

the ability to check the weight of a single pipe. It can also be

used to further adjust the traction speed of the production of this

pipe according to the increase in pipe weight. (This device does

not come with this feature by default, and additional hardware

implementation can be added according to customer needs)

5. The production line only needs to inspect the equipment

operators. When the winding film and packaging film are used up,

the system will alarm and prompt for replacement.

When faults occur in various parts, the touch screen will display

and sound and light alarms. The professional maintenance personnel

of the equipment press the corresponding emergency stop ,

reset and restart after handling the fault, and the production line

continues to operate fully automatically.

7. The Ethernet hardware port is reserved, and the software data

interface is open to facilitate the management of ERP enterprise

resource planning and MES Manufacturing execution system.

8. According to customer needs, customize the heat sealing method

for both ends of the bag opening or the automatic folding tape

wrapping method for sealing the bag opening. (The default is the

hot sealing method for both ends of the bag)

9. According to customer needs, you can choose a bagging device

suitable for any of the three sizes of packaging film, **0mm,

**5mm, and **0mm, for bagging packaging. You can also customize

special specifications of bagging devices.

| Country: |

China |

| Model No: |

-

|

| FOB Price: |

666 ~ 6666 / (Negotiable)

Get Latest Price

|

| Place of Origin: |

- |

| Price for Minimum Order: |

666 |

| Minimum Order Quantity: |

1 |

| Packaging Detail: |

- |

| Delivery Time: |

- |

| Supplying Ability: |

100000 per Year |

| Payment Type: |

PayPal, Other |

| Product Group : |

- |