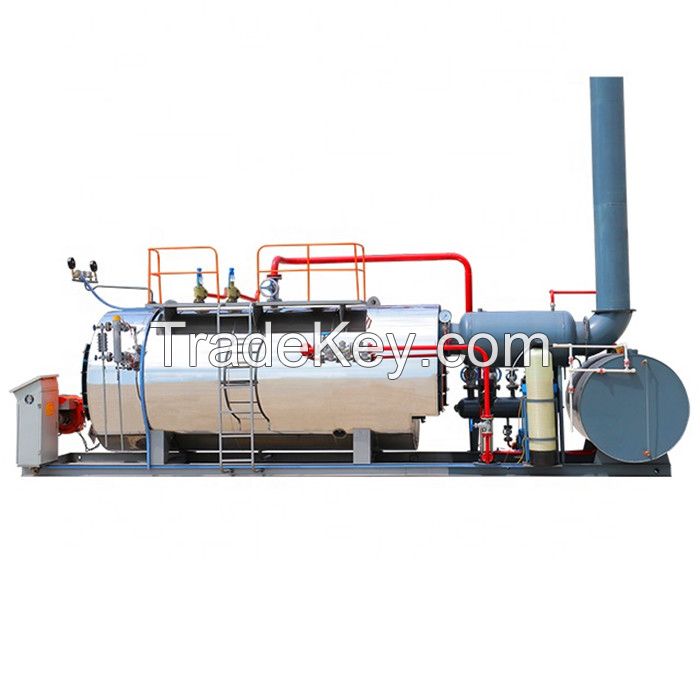

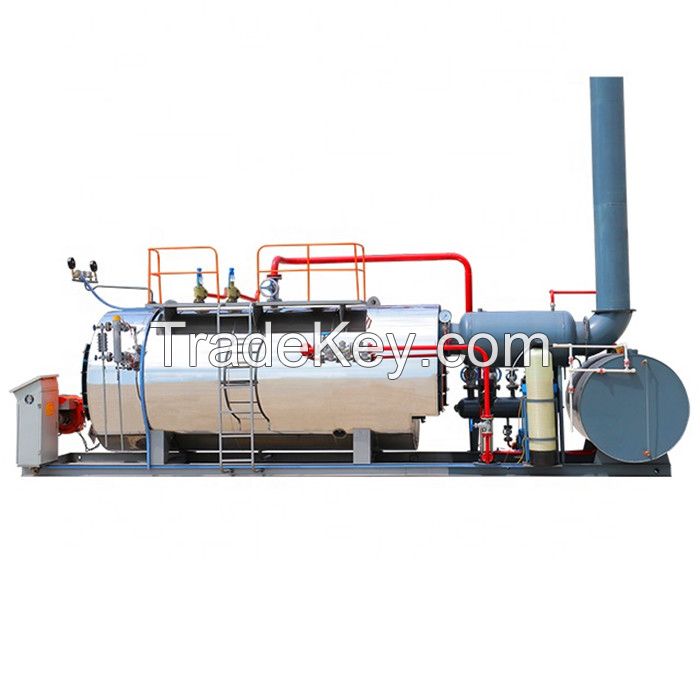

Product Description

Model: WNS Series Oil Gas Steam Boiler

Structure:Wet Back Fire Tube Packaged steam boiler

Fuel:oil, gas, light oil, heavy oil, natural gas, lpg, lng, cng,

diesel, biogas etc

Capacity:1-20 ton per hour

Pressure:0.7/1.0/1.25/1.6 Mpa (7/10/12.5/16 Bar)

Temperature:170/184/194/204 Celsius

Application:Chemical, food and brewery, pharmaceutical, package

plant, textile dyeing and printing industry, swimming pool,

hospital,school,clothing industry etc.

WNS

series is a classical shell type steam boiler, with classical

design: firetube+ wetback+ 3pass. Its average thermal efficiency

>95%, design working life span more than 15 years. Equipped with

well-known auxiliary parts, such as BALTUR/RIELLO- Burner, DANFOSS-

Pressure Controler, SIEMENS- PLC operation system, LEO- Multistage

Pump, etc. to ensure the boiler's steady performance. The entire

system warranty period: 2 Years.

Free-Installation

Before

the shipment, complete boiler system is well skid-mounted on the

basement, also we have done the pipe(valves) connection and wire

connection. After receiving the boiler, no need installation/

assembly. Just join the boiler to water/ gas/ electricity.

Comparing with other traditional boilers in the market, our boiler

does save lots of cost/ energy/ time in installation. The

additional, the entire boiler system is

portable.

When

industrial steam boiler goes out of the factory, it is composed of

three parts: the main boiler, the chimney and the pipeline system.

The main body and the chimney have been manufactured in the

factory, and the supporting pipeline valves and instruments of the

main boiler have been installed randomly, and then transported to

the site to assemble the main body and the chimney.On the spot

connect the air source, power supply and water pipeline to start

the test.Greatly shorten the installation cycle, and can guarantee

the quality of boiler.

Technical Specification

|

Model |

Rated |

Rated |

Rated |

Thermal |

Fuel Consumption |

Equipment Power |

Weight |

|

Capacity

(t/h)

|

Pressure

(Mpa)

|

Temperature

(C)

|

Efficiency

(%)

|

Light oil

(Kg/h)

|

Natural gas

(Nm³/h)

|

Burn

light oil

|

Burn

gas

|

(t) |

|

WNS1 |

1 |

0.7/1.0/1.25 |

170/184/194 |

>90 |

45-100 |

18-100 |

1.5 |

1.5 |

4 |

|

WNS1.5 |

1.5 |

>90.2 |

101.73 |

123.47 |

2.2 |

1.5 |

5 |

|

WNS2 |

2 |

1.0/1.25/1.6 |

184/194/204 |

>90.2 |

137.09 |

165.97 |

2.2 |

3 |

8 |

|

WNS3 |

3 |

>91 |

205.75 |

249.6 |

7.5 |

7.5 |

9 |

|

WNS4 |

4 |

>91 |

272.3 |

329.5 |

9 |

7.5 |

13 |

|

WNS5 |

5 |

>91.5 |

134-402 |

80-500 |

17.2 |

15 |

15 |

|

WNS6 |

6 |

>91.5 |

134-402 |

80-500 |

15 |

15 |

17 |

Boiler Features:

1. The design, production, supervision and inspection of boilers

are strictly in accordance with the Safety Supervision Regulations

for Steam Boilers, JB/T 10094-2002 General Technical Conditions for

Industrial Boilers, and JB/T 1619-2002 Technical Conditions for

Boiler Body Manufacturing, so as to ensure long-term safety and

stability of boilers.

2, the body for the pot shell type full wet back downstream three

return firework tube structure, the flame in the large combustion

chamber micro positive pressure combustion, complete extension, low

burning heat load, less NOx emission of harmful substances.

3, corrugated furnace and threaded pipe structure, that is, to

improve the strength, but also to meet the needs of the heat

expansion of each part.

4. Butt joint is adopted in the welding of the main welding seam,

and non-destructive inspection is conducted by X-ray and ultrasonic

to ensure that the welding quality meets the national

requirements.

5, the boiler water volume and gas space is large, strong capacity

to adapt to the load.Reasonable design of boiler installation, to

ensure that the steam water rate is less than 4%, to meet the

higher requirements of users on the quality of steam.

6, the use of new heat insulation material, light weight, less heat

loss, good insulation performance.

7. The water level alarm adopts stainless steel as electrode rod

and teflon as insulation material.Inserted from the top, not easy

to hang dirt, reliable performance, long service life.

8. The front and rear smoke boxes are connected by hinges, which

can be easily opened, convenient for maintenance and

maintenance.

| Country: |

China |

| Model No: |

WNS4-1.25

|

| FOB Price: |

( Negotiable ) (Negotiable)

Get Latest Price

|

| Place of Origin: |

China |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

1 Set |

| Packaging Detail: |

wooden package |

| Delivery Time: |

15 to 20 days |

| Supplying Ability: |

100 Set per Month |

| Payment Type: |

Western Union, L/C, T/T |

| Product Group : |

Steam Boiler

|