FOB Price

Get Latest Price( Negotiable )

|20 Kilogram Minimum Order

Country:

China

Model No:

DS-carbomer-12

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

Ezhou city,Hubei province,china

Price for Minimum Order:

-

Minimum Order Quantity:

20 Kilogram

Packaging Detail:

20kg/paper package

Delivery Time:

4-10 days

Supplying Ability:

1000 Kilogram

Payment Type:

T/T, L/C

Product Group :

Contact Person jing zhao

Business Address:C8-2, Optics Valley United Technology City, Huarong District, Ezhou, Hubei

| Country: | China |

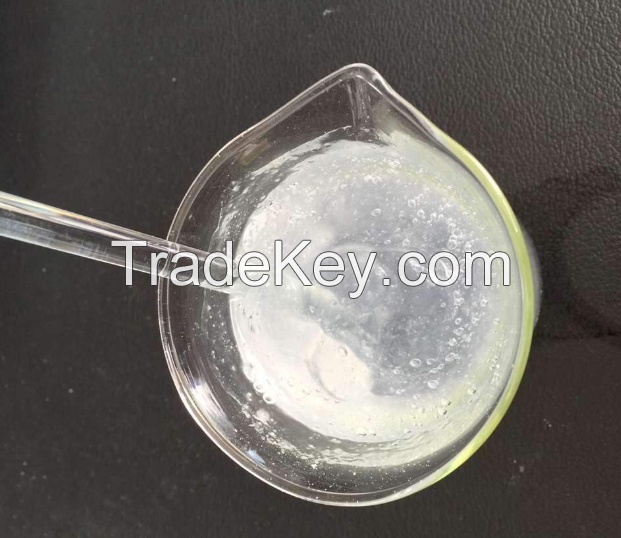

| Model No: | DS-carbomer-12 |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | Ezhou city,Hubei province,china |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 20 Kilogram |

| Packaging Detail: | 20kg/paper package |

| Delivery Time: | 4-10 days |

| Supplying Ability: | 1000 Kilogram |

| Payment Type: | T/T, L/C |

| Product Group : | Carbomer |